Change in positioning axis or direction

Change in positioning axis or direction

Change in Positioning/ Fastening Direction

|

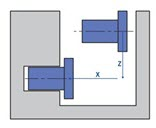

Change in positioning axis or direction refers to the components, that require a change of the axis or direction (leaving the defined positioning axis) in order to reach its final position.

A change in positioning direction becomes necessary, if a component or sub-assembly has to be positioned in more than one direction along a defined positioning axis.

A change in fastening direction exists if a component or sub-assembly has to be fastened in more than one fastening axis/direction at the destination.

|

Explanation

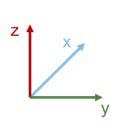

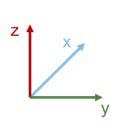

The aim should be to position and fasten all components or assemblies in only one direction. This requires defining a coordinate system in order to illustrate the defined positioning axis and positioning or fastening directions.

|

|

Defining a coordinate system

|

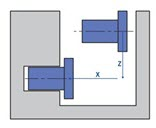

Change in positioning direction

|

Example:

Changing of positioning and fastening direction

|

|

Defining a coordinate system

|

The z-axis is the main assembly direction from top to bottom

|

Change in positioning direction (= change of coordinate axis) and in fastening direction (change in direction on the same coordinate axis)

|

Change in axis

|

Change in direction

|

z-axis

|

|

|

4 bolts (assembly position)

|

0

|

0

|

from z-axis to y-axis

|

|

|

2 bolts (left side)

|

1

|

0

|

change in direction on y-axis

|

|

|

2 bolts (right side)

|

0

|

1

|

from y-axis to x-axis

|

|

|

1 bolt

|

1

|

0

|

|

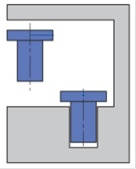

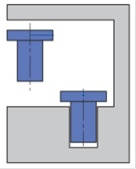

Restricted space

Restricted space

The restricted space requires additional motions and/or results in delays for the positioning.

Example:

|

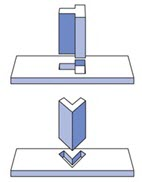

Aligning basic or positioning part

Aligning basic or positioning part

The part to be positioned or the basic part has to be turned around the positioning axis. As a result, the joining cross-sections will be congruent.

Example:

|

Measure and/or check per criterion

Measure and/or check per criterion

Measure and/or check per criterion

|

Measure and/or check per criterion describes measurements or inspections of quality characteristics resulting from the design.

|

Explanation

The measurement or inspection is done by using cameras, scanners, sensors, actuators, etc.

Examples:

•Tolerances

•correct position

•correct part

Rule A-M1:

|

If before, during or after positioning, design-caused measurements or inspections are required, they have to be evaluated with the relevant frequency.

|

|

Readjustment

Readjustment

Readjustment

|

Readjustment refers to design-caused processes that must be performed prior to completing subsequent activities.

|

Explanation

Readjustment can be necessary as an independent activity for aligning or adjusting processes.

Rule A-J1:

|

If after positioning, design-caused adjustments are required, they have to be evaluated with the relevant frequency.

|

Rule A-J2:

|

Required measurements or inspections are not considered in the value and have to be analyzed separately.

|

|

Flexible part

Flexible part

Flexible part

|

Flexible part describes a component to be positioned, that is not dimensionally stable and requires appropriate support when being positioned.

|

|

Additional securing while positioning

Additional securing while positioning

Additional securing while positioning

|

Additional securing while positioning describes a basic part and/or component, that has to be secured additionally during positioning.

|

Explanation

Additional securing while positioning is required, if huge forces occur or if the component hasn’t been finally fixed yet.

|

Without positioning aids

Without positioning aids

Without positioning aids

|

Without positioning aids refers to an assembly process in which neither the component or sub-assembly, nor the positioning location, is equipped with positioning aids, such as bevels, pivots, stops etc.

|

Explanation

Missing positioning aids inevitably result in assembly interferences.

Examples:

|

|

Without positioning aid

|

with positioning aid

|

|

![]() Change in positioning axis or direction

Change in positioning axis or direction![]() Aligning basic or positioning part

Aligning basic or positioning part![]() Measure and/or check per criterion

Measure and/or check per criterion![]() Additional securing while positioning

Additional securing while positioning