Converting ProKon units into real time values

The analysis criteria on the ProKon analysis sheet describe influencing factors that affect the assembly time. However, additional influencing factors that are required to accurately represent the total assembly time are not present in the description.

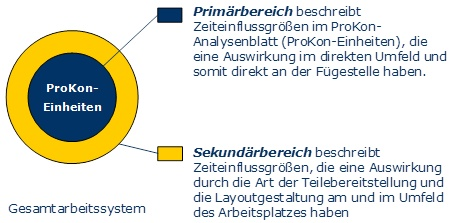

To understand this issue, the work system can be divided into primary and secondary sectors, as shown in the graph below.

Time-influencing factors in the overall work system

The ProKon Analysis provides quantified data, in the form of Units, defining the primary sector. However, the ProKon Analysis does not provide such quantified data for the secondary sector.

To determine the data for the overall work system, an analysis of the time required for the real work process is carried out first. Bearing in mind that ProKon should be applied at an early stage of the product development process, it is obvious that a real record of the process is not possible. However, the following options are available for obtaining the required data:

•Creation of an MTM planning analysis based on the parameters defined for the future work system to be established for the new product

•Reference to existing MTM data previously developed for a sufficiently comparable product, while adjusting details, where required

•Comparison with a reference product, while estimating significant deviations

The time value established is utilized in the calculation of the factor, as described below:

![]()

Example:

For an assembly consisting of eight components, an assembly time of 1.2 minutes has been determined. The ProKon analysis for the expected assembly process yields a total of 1,500 units.

From this result the factor is:

![]()

When developing the factor, it is advisable to repeat this procedure for a number of products and assemblies representing comparable work systems to establish a statistical average for the factor. It is important to ensure that the factor is determined for comparable work systems, i.e. work systems with a comparable secondary sector. The conversion factor must therefore be determined for each industry. For example, it could be 0.0008.

Using the factor

By rearranging the above formula, the factor can be used during the design stage to estimate initial assembly times for newly designed products or sub-assemblies, where the ease of assembly has been quantified with ProKon, avoiding the need for knowledge of the future work system.

The work area (secondary sector) of a quantified product or sub-assembly has to be comparable to the work area from which the factor was determined.

∑ Units × Factor = Assembly Time (min)

Example:

The ProKon analysis for an assembly yielded 2,150 units. This results in the calculation of the following assembly time: 2150 × 0.0008 = 1.72 min

Note: |

The estimated assembly time of 1.72 min is equivalent to the basic time (tg). Basic time does not include allowance time or other additions. |